Infrastructure

State-of-the-Art Infrastructure and Innovation

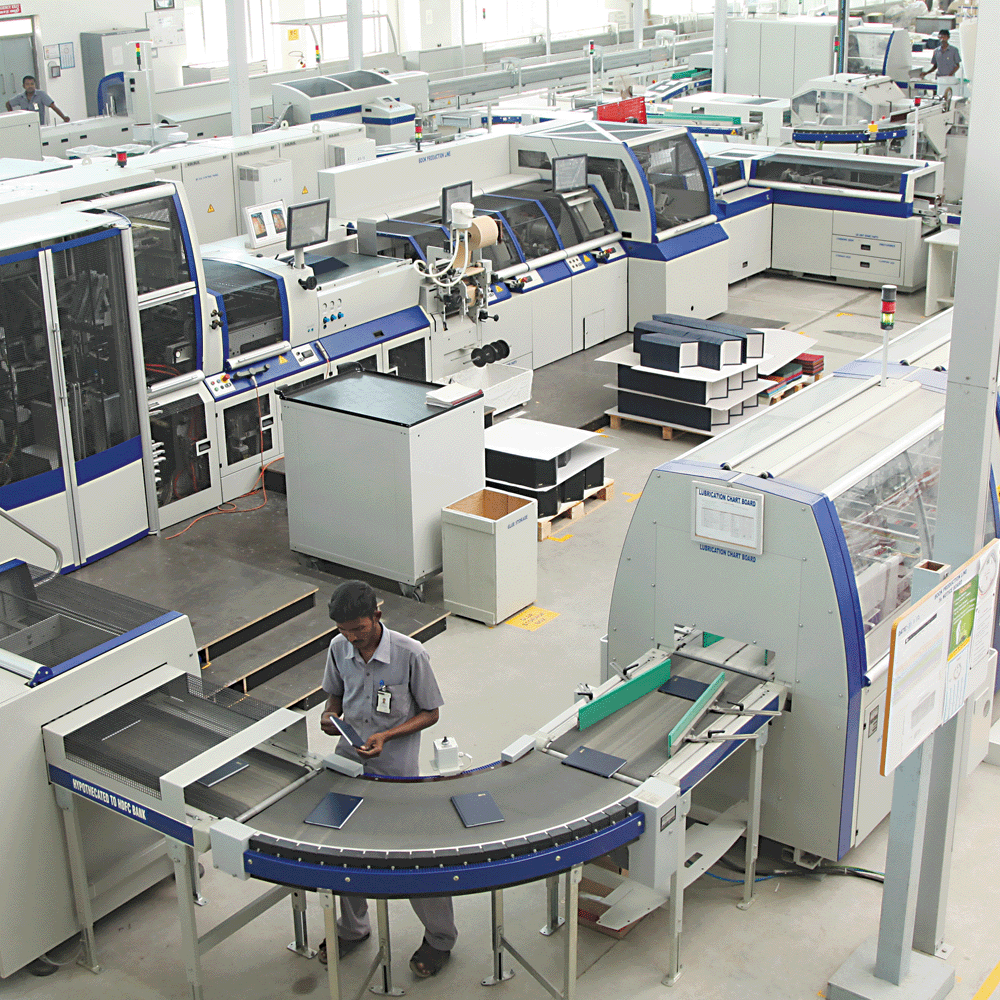

Our production infrastructure is among the most advanced in the industry, spanning large, modern facilities including a 65-acre upcoming print city in Sivakasi. Equipped with cutting-edge offset and digital presses, we offer end-to-end in-house production—from pre-press to automated finishing. SFAPL remains at the forefront of print innovation through continual investment in technology.

Our commitment to innovation means we continuously update and upgrade our machinery. This integration of modern technology not only increases our productivity but also expands the creative possibilities we can offer to clients. Whether it’s experimenting with new inks and substrates, or implementing the latest digital printing techniques, SFAPL strives to stay ahead of industry trends. Our expert technical team – many with decades of experience – work in tandem with these advanced machines, ensuring that the human touch and expertise guide every high-tech process. The result is a seamless synergy between craftsmanship & technology, enabling us to deliver products that are both beautiful and flawlessly produced.

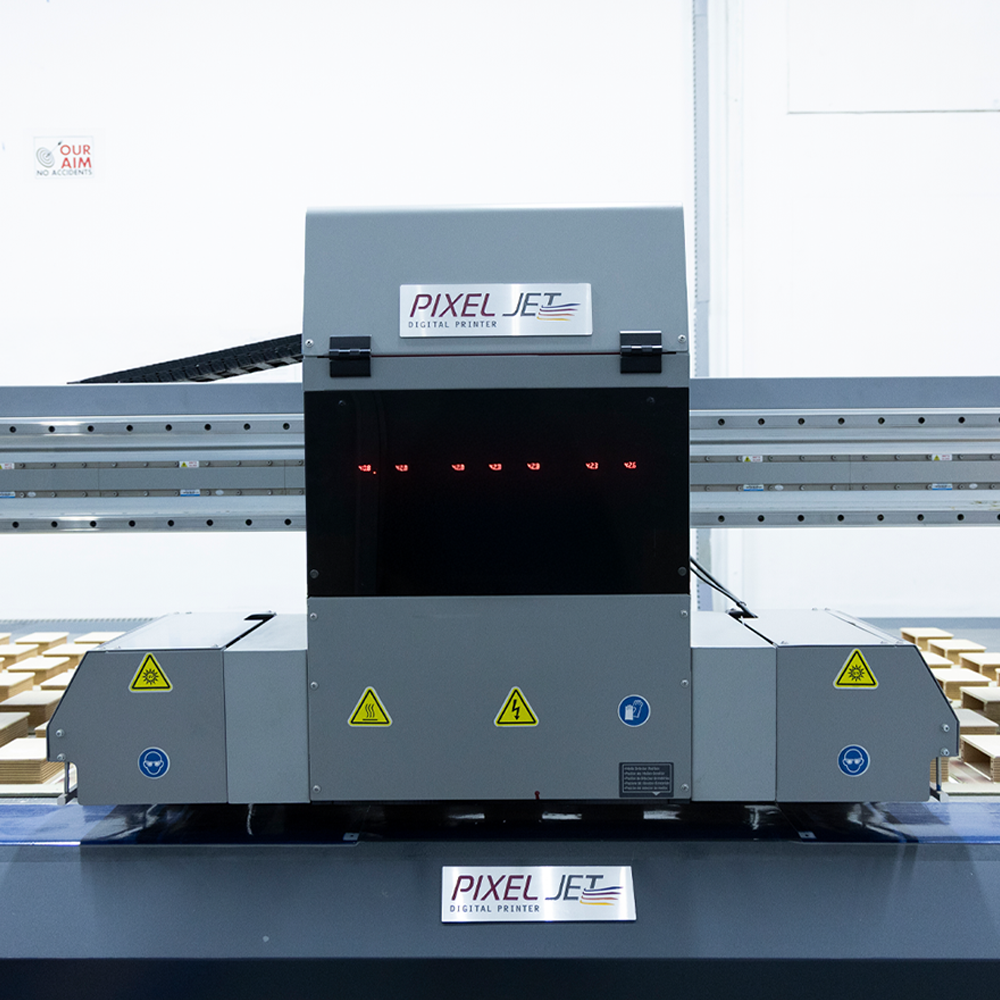

In our press halls, you will also find the Fujifilm Revoria Digital Colour Press, a cutting-edge digital printing press known for its superb color reproduction and efficiency. This advanced printer allows us to deliver short-run and personalized print jobs with the same finesse as mass productions, catering to the growing demand for customization without compromising on quality. Alongside these, our infrastructure includes numerous high-speed binding and automated embellishment units – which together enable us to produce books and stationery in large volumes while maintaining handcrafted quality.

Printing Machines -Heidelberg 6/4 color UV press with coater(CD 74 / SM102), Akiyama Reel fed 8 colour Press, array of Single Colour perfector presses.

- Image Controller – for print quality management we have Heidelberg image controller.

Fujifilm Revoria Digital Colour Press – for high-resolution, six-color digital printing with exceptional vibrancy and detail.

Scodix Ultra Digital Embellishment Press – for cutting-edge print embellishments like digital spot UV, embossing, foil stamping, and other tactile finishes that elevate our products’ luxury appeal.

- Case Maker – For Case making we have Harauf & Kolbus Da280 (100 cases/min).

- Folding – we have array of Automatic Shoei Paper Folding Machine (10 nos.)

- Sewing Machine – 21 station gatherer connected to 3 nos of Aster 220C machine with Signal X camera and Image reader, 36 station gatherer connected to 2 nos of HXCP 220 and Yasi Sewing Machine connected with 24 station gatherer .

- Automated Binding & Finishing Lines – a suite of high-speed binding, trimming, and packaging systems (including Kolbus BF530, Kolbus KM600, and Sigloch Book Block machines) that ensure efficiency and accuracy in delivering final products.

- Personalisation – we have Gold letter Hot Foil Stamping Machine, Monotech Systems & Polar Digital Cutting Machine for Personalised name foiling, UV printing and Engraving solutions

- Packaging Machines – Spanthra 106LE for Die Cutting, Bobst Mistral 80 for box pasting, Brausse 1050 for Foil cum Diecut

We were the first in India to install the Scodix Ultra 6500 SHD Digital Embellishment Press, a state-of-the-art press that gives us unrivaled capabilities in adding 3D UV coating, foil, texture and other premium enhancements to printed materials. This pioneering move has been a game-changer in our high-end finishing department, allowing us to offer unique creative finishes and effects that set our products apart globally.